LCD

The glass substrate is a thin glass sheet with an extremely flat surface, and is one of the important raw materials for liquid crystal display panels. The key supporting materials of liquid crystal panels include glass substrates, optical films, liquid crystal materials, polarizers and other materials. The panels can be divided into three types: LCD panels, OLEDs and mini LEDs. LCD panels require that the glass substrates must be alkali-free glass; and OLED panels in order to achieve Higher resolution, higher brightness, longer service life and other features have higher requirements for glass substrates.

Glass Substrate Processing Technology

The glass substrate production process can be divided into Float Technology, Overflow Fusion Technology and Slot Down Draw. At present, Asahi Glass is the only company in the world, AGC, which uses the float method to manufacture TFT-LCD glass substrates. The current mainstream production process in the industry is the overflow fusion method.

Glass Substrate Thinning Process

Plastic Closures ——— Etching/Thinning ——— Grind ——— Cleaning

Yuhuan Corresponds To Polishing Equipment

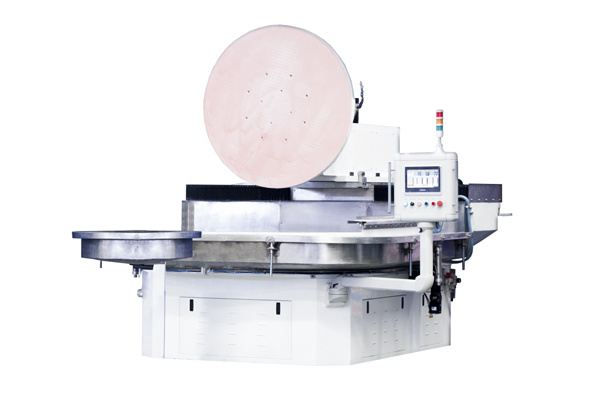

YHJ81190 Precision Single-Side Polishing Machine

Equipment features: remove glass scratches, thinning and polishing, ultra-thin processing, large size

Processing requirements: large-size LCD panel automatic polishing line

Response plan description: With YHJ81190A high-precision single-side polishing machine as the core, a complete set of automatic production lines for LCD panel polishing are built, which can realize high-precision polishing on both sides of LCD panels, automatic loading and unloading, flipping, transmission and other cleaning and drying, etc. A complete set of production processes.

In addition to the YHJ81190A high-precision polishing machine, the main equipment also includes manipulators (including glass forks, rails, etc.), glass material placement racks, glass suction fixtures, transmission lines, etc. The glass transmission line is arranged according to the customer's site space to save space as much as possible.