Traditional Car

1. Gasket

● Processing Technology

Stamping ➤ Rough grinding ➤ Leveling ➤ Medium grinding ➤ Hardening ➤ Fine grinding ➤ Deburring

| Thickness(mm) | Diameter(mm) | Flat(mm) | Parallel(mm) | Size(mm) | Margin(mm) | Hardness(mm) | Material | Grinding wheel | Roughness |

| 0.55-3 | 45-99 | 0.01 | 0.01 | ±0.005 | 0.03-0.2 | 30-50 | 65Mn\dc01 | Fine grinding CBN | Ra0.6 |

● Double Face Grinding Solutions

The differential gasket needs to be finely ground with 580B after middle grinding and quenching (Note: According to the requirements of the main engine factory, it can be divided into before and after quenching)

YHDM580B + CBN grinding wheel = automotive adjusting shim

2. Transmission gear

● Gear double-sided grinding process

Forging ➤ Normalizing ➤ Turning ➤ Hobbing, Shaping ➤ Shaving ➤ Heat Treating ➤ Grinding (reduce geometric tolerance)

| Thickness(mm) | Diameter(mm) | Flat (mm) | Parallel(mm) | Dimensions (mm) | Margin(mm) | Hardness(mm) | Material | Grinding wheel | Roughness |

| 0.55-3 | 45-99 | 0.01 | 0.01 | ±0.005 | 0.03-0.2 | 30-50 | 65Mn\dc01 | 精磨CBN | Ra0.6 |

● Grinding Solutions

Thickness higher than 8mm: 300/580B-5/77 series planetary oscillating grinding for one grinding; thickness less than 8mm: choose 580, 750 C type for multiple grinding according to the diameter; single-side grinding: 7418 is recommended

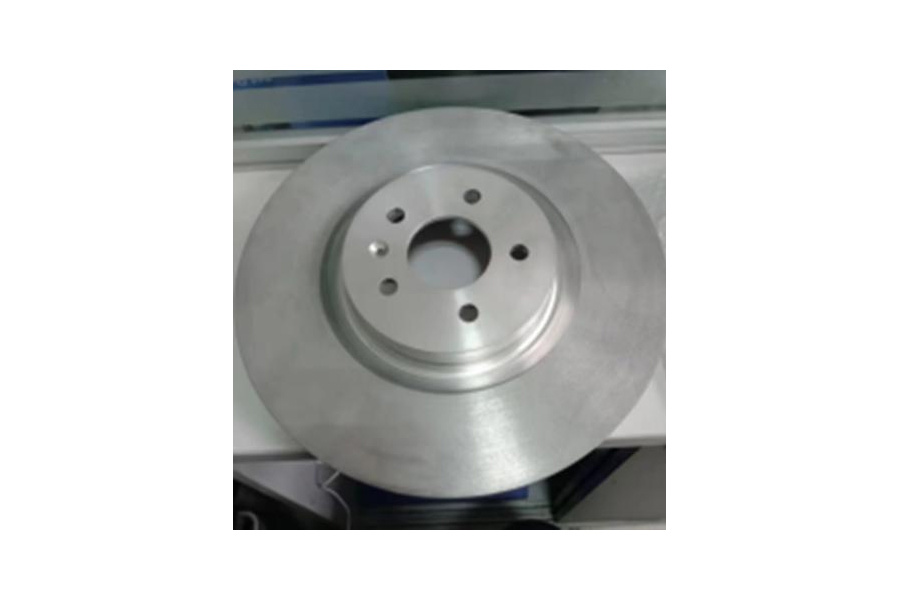

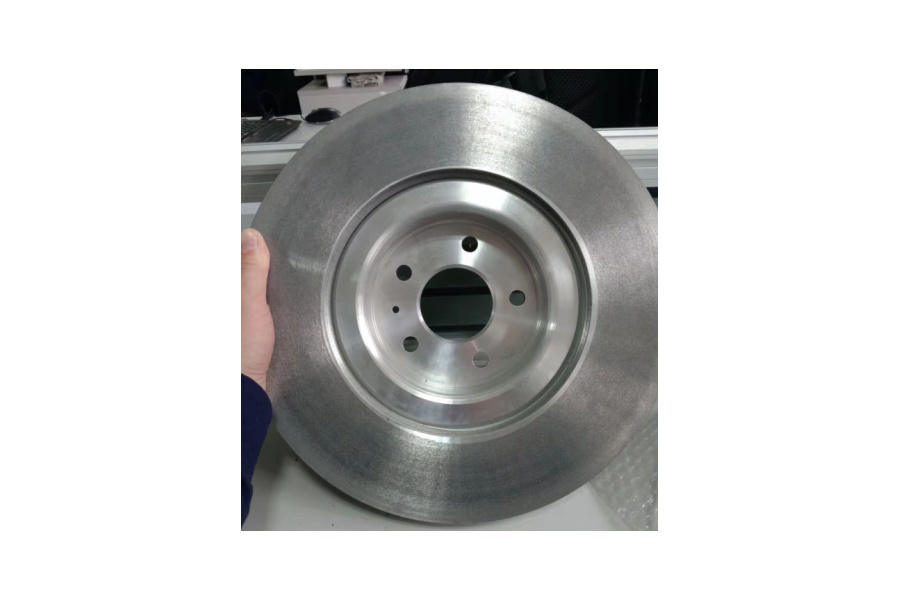

3. Brake Disc

Workpiece material: aluminum matrix composite material

Processing technology: double-sided grinding

Processing requirements: flatness Ra0.025

|

|

4. Connecting Rod

Workpiece size: length 250mm, thickness 28.4mm

Workpiece material: 45Cr steel

Rockwell hardness: 32-36

Removal amount: 0.8mm

Processing equipment: YHDM750A high-precision vertical double-end grinding machine

Processing method: swing grinding

Processing technology: double-sided grinding to reduce thinning

Processing efficiency: 30 s (15 s/pc)

Flatness/parallelism after processing: ≤0.02mm

Surface roughness after machining: ≤0.5 Ra

5. Piston Ring

Workpiece size: diameter 120mm, thickness 1.8mm, hardness 95-106 HRB

Workpiece material: gray cast iron

Removal: 0.12-0.13mm, the first removal is 0.085mm, and the second removal is 0.035-0.045 mm

Processing equipment: YHDM750A high-precision vertical double-end grinding machine

Processing technology: double-sided grinding to reduce thinning

Processing efficiency: 0.6s/pc, 6000 pc/hour

Size control: ±0.005 mm

Flatness/parallelism after processing: 0.004mm

Surface roughness after machining: 0.25 µm Ra

6. Large Retaining Ring

Workpiece size: diameter 110mm

Grinding size requirements: 3.300mm±0.012

Processing technology: double-sided grinding to reduce thinning

Processing equipment: YHDM750 high-precision vertical double-end grinding machine

7. Stator Rotor

Workpiece material: powder metallurgy

Processing technology: double-sided grinding to reduce thinning

Processing equipment: YH2M8470 high-speed double-sided precision grinding machine

Surface roughness after processing: ≤Ra 0.5

Processing efficiency: 0.6 S/PC

Flatness/parallelism after processing: ≤0.002 mm

Removal amount: 150-200um

Thickness control: ≤3um