Double-sided gasket thinning

1. Gasket

● Machining Process

Stamping ➤ Rough Grinding ➤ Leveling ➤ Medium Grinding ➤ Quenching ➤ Fine Grinding ➤ Deburring

| Thickness (mm) | Diameter (mm) | Plane (mm) | Parallelism (mm) | Dimensions (mm) | Allowance (mm) | Hardness (mm) | Material | Grinding Wheel | Roughness |

| 0.55-3 | 45-99 | 0.01 | 0.01 | ±0.005 | 0.03-0.2 | 30-50 | 65Mn | Fine Grinding CBN | Ra0.6 |

● Double-ended Grinding Solution

Differential gasket requires medium grinding and quenching, followed by fine grinding with 580B (Note: According to the requirements of the host factory, it is divided into before and after quenching).

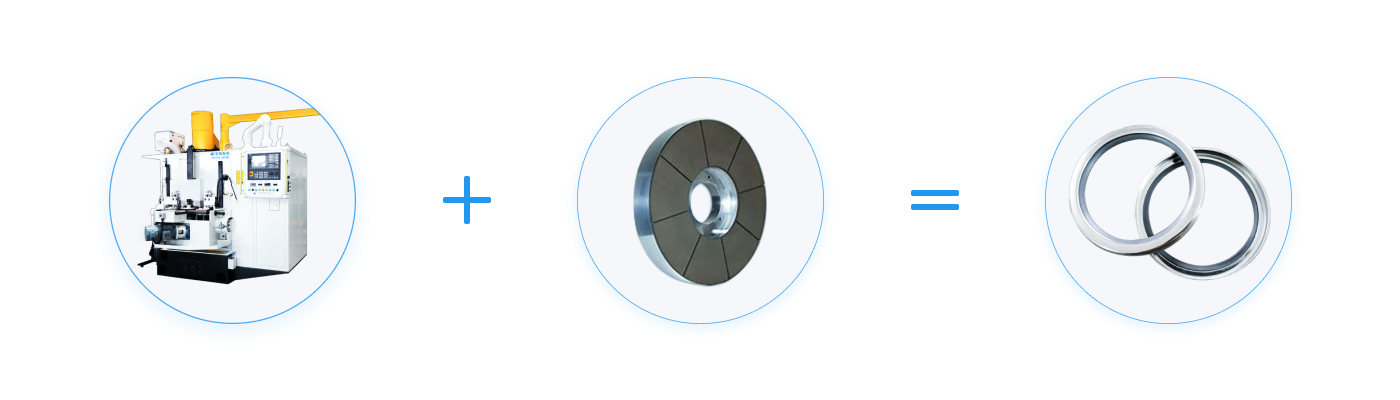

YHDM580B + CBN grinding wheel = Automotive adjustment gasket

Core Objectives:

Precisely control the final thickness: Achieve the precise dimensional tolerance required by the drawings (usually micron level).

Ensure high parallelism: The parallelism between the two ground surfaces is crucial and directly affects the sealing performance.

Obtain good surface quality: The surface roughness must meet the requirements to avoid burns, scratches, and other defects.

High-efficiency production: Improve grinding efficiency and reduce costs while ensuring quality.